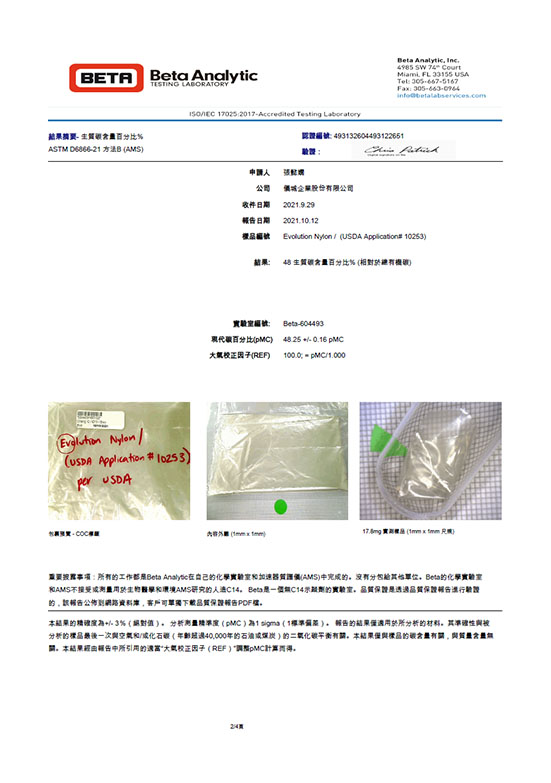

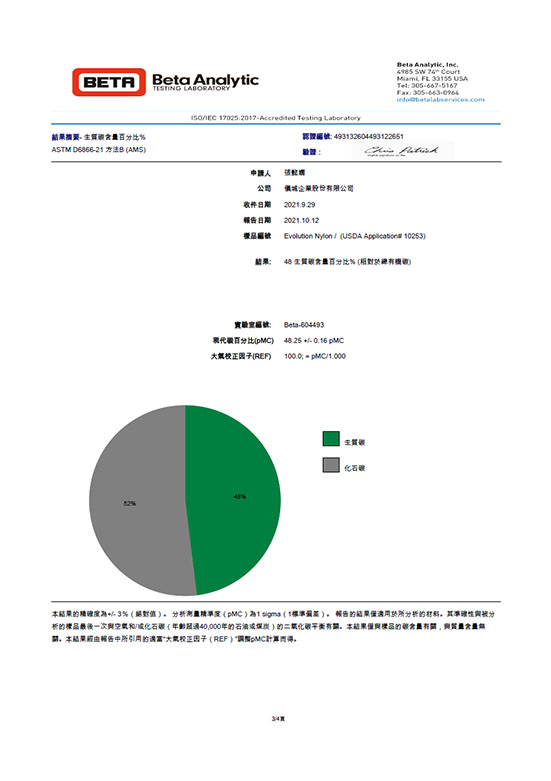

Castor oil,Bio-based material

Pebax® Rnew® elastomer pellets

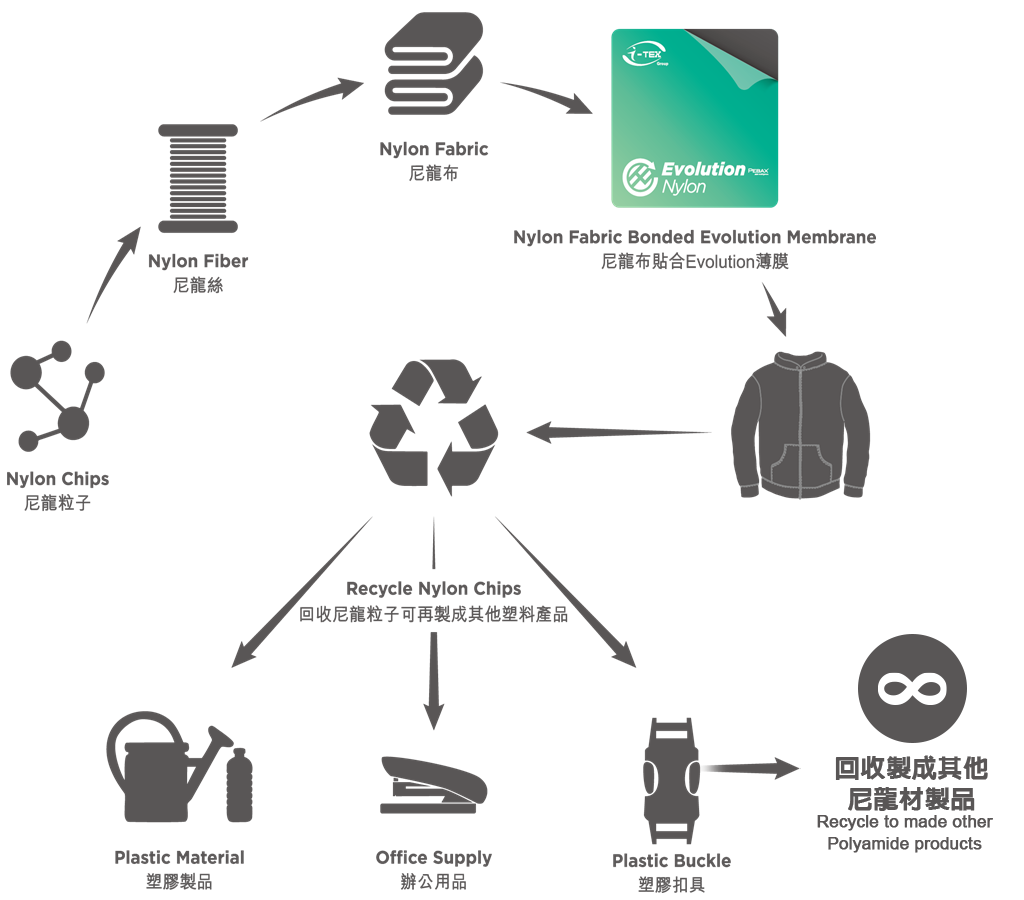

Evolution Nylon Film Process Nylon pellets are stretched and dried by hot-melting process, the additive are added during the hot-melting process to ensure the stability of the film. Polyether block amide (PEBA) is made from nylon material (PA) and polyether. In the manufacturing process,which can increase the toughness and elongation, modify the rigidity property of nylon.

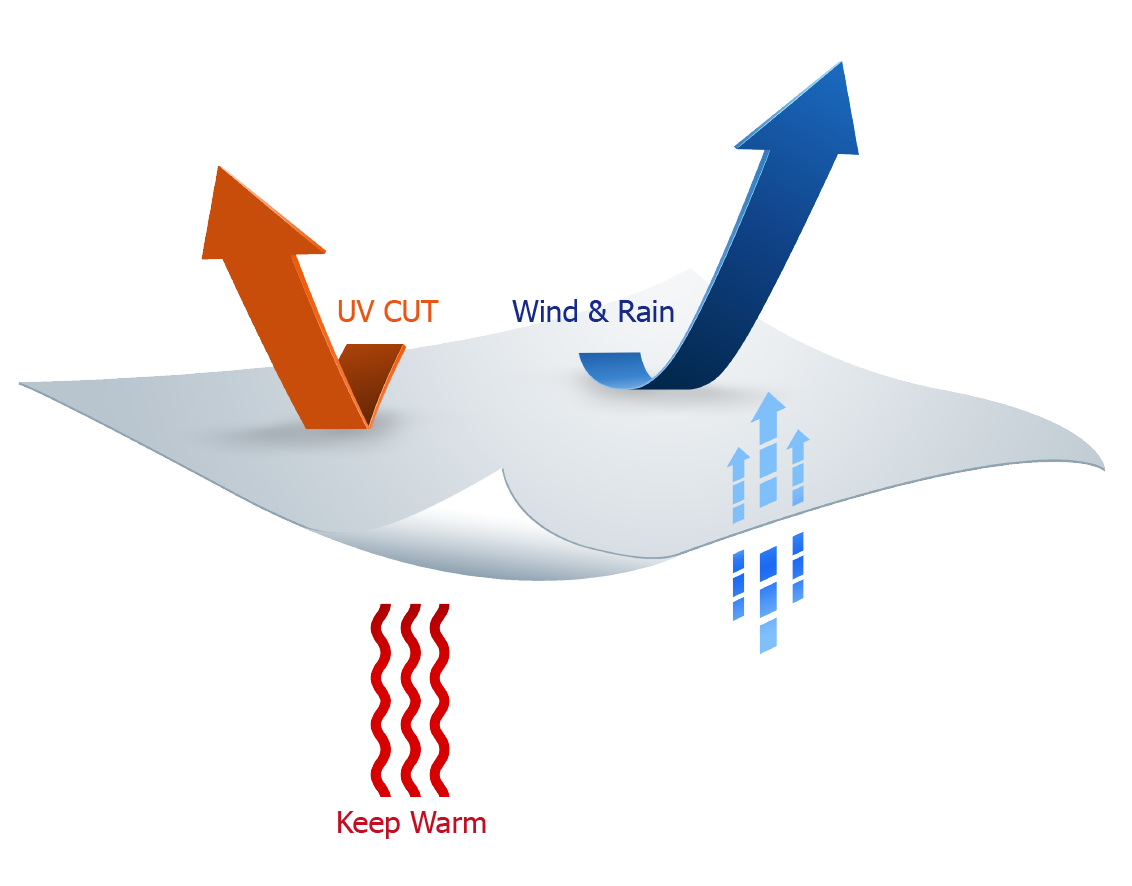

High Function and Unique Bio Based

| Testing | Standard | Sample | Unit | Warp |

|---|---|---|---|---|

| Thickness | Vendor method | Blowing film | mm | 0.018 |

| 100%M | ASTMD882 | Blowing film | Kg/cm2 | 72 |

| 300%M | ASTMD882 | Blowing film | Kg/cm2 | 91 |

| Tensile strength | ASTMD882 | Blowing film | Kg/cm2 | 127 |

| Elogation | ASTMD882 | Blowing film | Kg/cm2 | 524 |

| Tearing Strength | ASTMD882 | Blowing film | Kg/cm | 99 |

| Water Resistance | JIS L1092B | Blowing film | mmH2O | 20000 |

| Water Vapor Permeability | JIS Ll099 Bl | Blowing film | g/m2-24hrs | 180000-200000 |

| Water Vapor Permeability | ASTM E96-05BW | Blowing film | g/m2-24hrs | 10000 |

T478-17001TW Patent Certificate Taiwan

O478-17001EP Patent Certificate

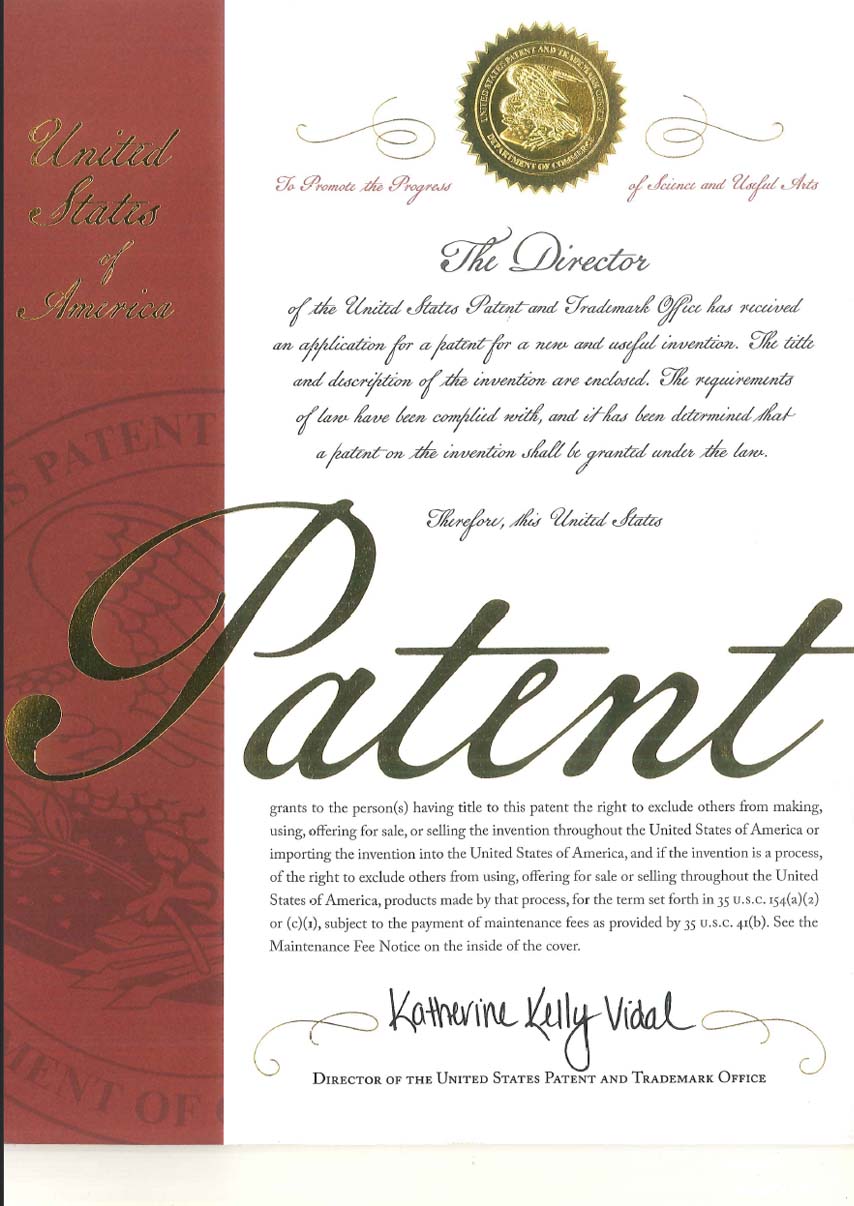

O478-17001CUS Patent Certificate USA

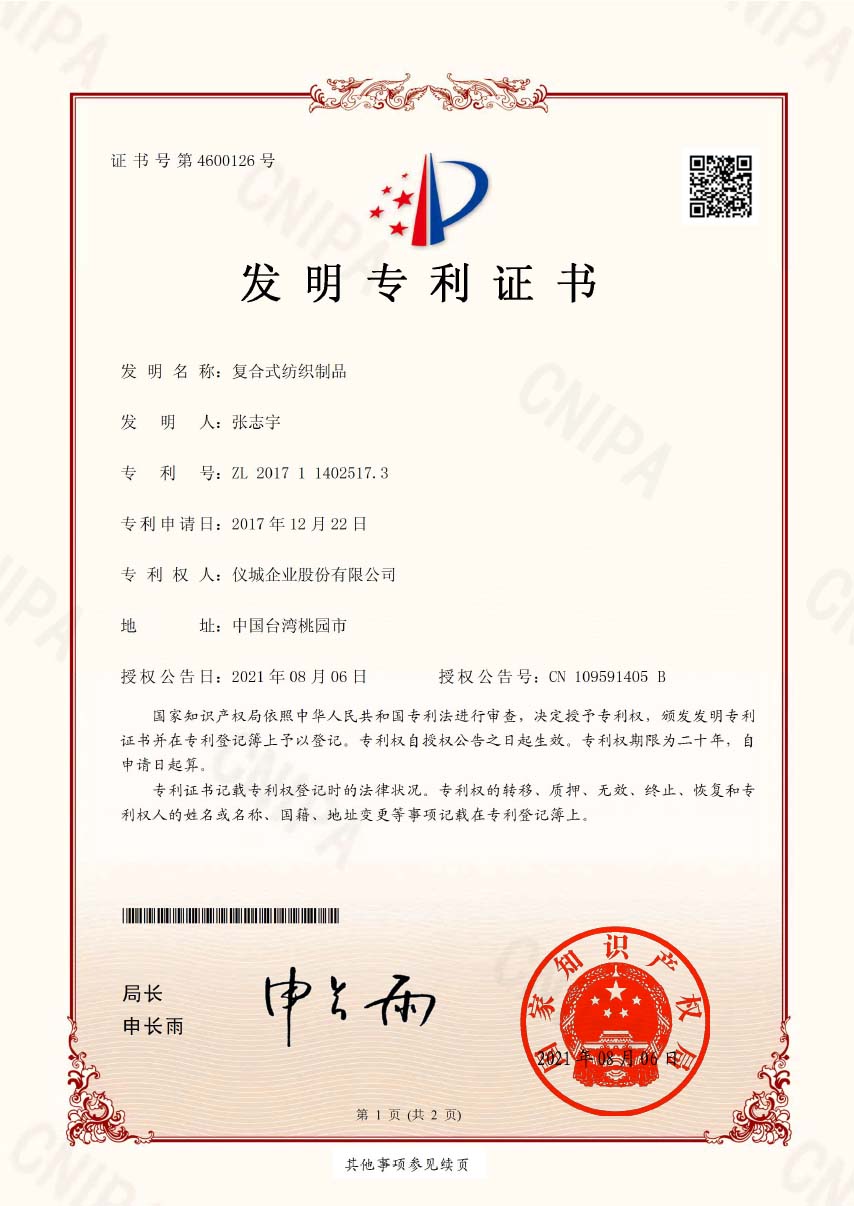

O478-17001CN Patent Certificate China